Concept

Boost the performance of Circular Manufacturing Systems

Circular TwAIn is developing a novel AI platform for circularity with the aim to increase the performance, resilience, and sustainability of direct manufacturing and process industries.

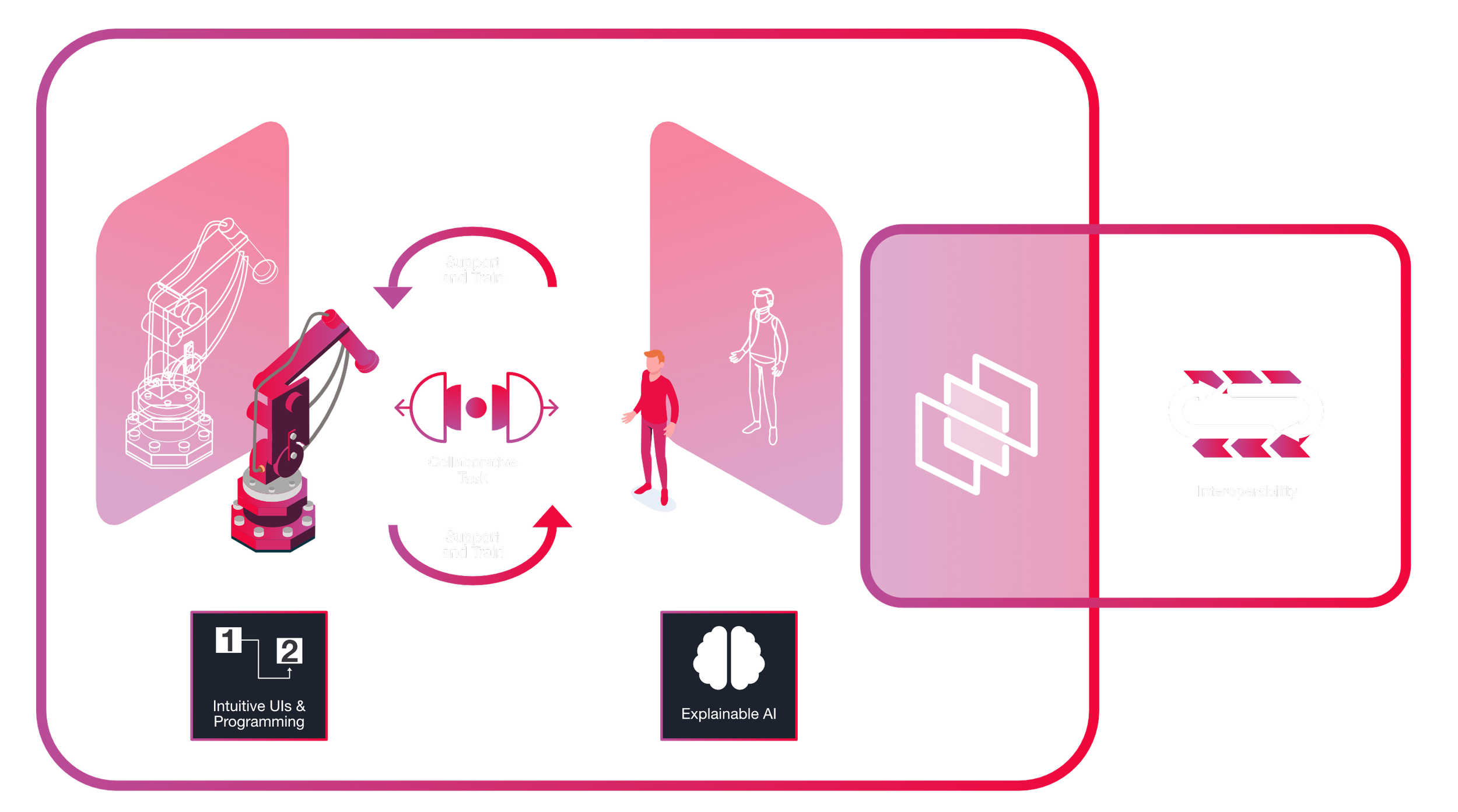

The project is based on 2 fundamental concepts.

Collaborative AI and

Seamless Data Sharing.

Collaborative AI

AI technology is seen as meaningful support for the human worker on the shop floor – not as a replacement. The collaborative approach aims to reach performances that man or machine, acting independently, cannot reach.

Seamless Data Sharing

Technical and semantical interoperability as well as trustworthiness between all actors of the circular manufacturing system is vital.

Objectives